Technical Articles

The Design Engineer’s Role in Casting Procurment

It is a well-known axiom that 70% – 90% of the cost of a product is the result of design decisions. Although we might debate as to the preciseness of this estimation the fact remains that design is key element to the manufacturability, availability, reliability and overall affordability of any manufactured product. Castings are inherently…

Read MoreInvestment Casting (Al/SiC) Metal Matrix Composites

The particulate Silicon Carbide reinforcement in Aluminum Alloy Metal Matrix Composite enhances this lightweight material with improved mechanical property attributes for stiffness, vibration dampening, wear resistance, high thermal conductivity, and low coefficient of thermal expansion. With its unique set of properties MMC alloys have been employed in diverse applications such as moving structures in high…

Read MoreCustomer Quality Cross Training

The Sales Engineering team at O’Fallon Casting acts as the primary point of contact between the business and its customers. Because of this, it is critical that all of the technical and quality requirements of customer products are understood by each Sales Engineer. Additionally, the Sales Engineer is responsible for verifying the contract requirements and…

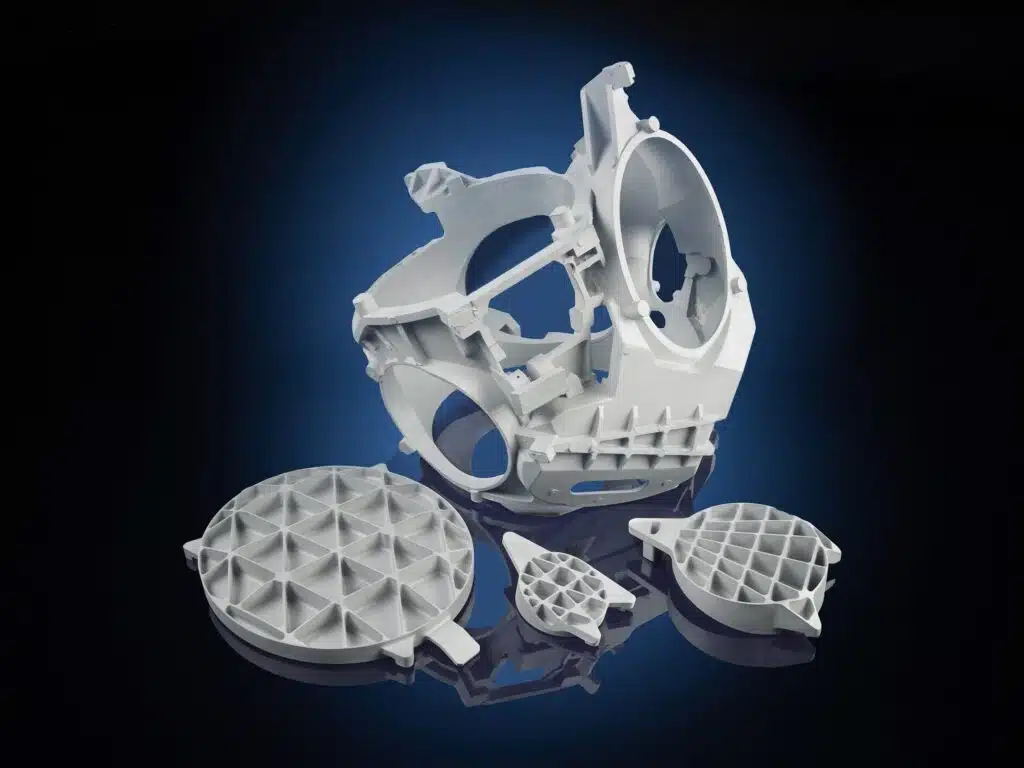

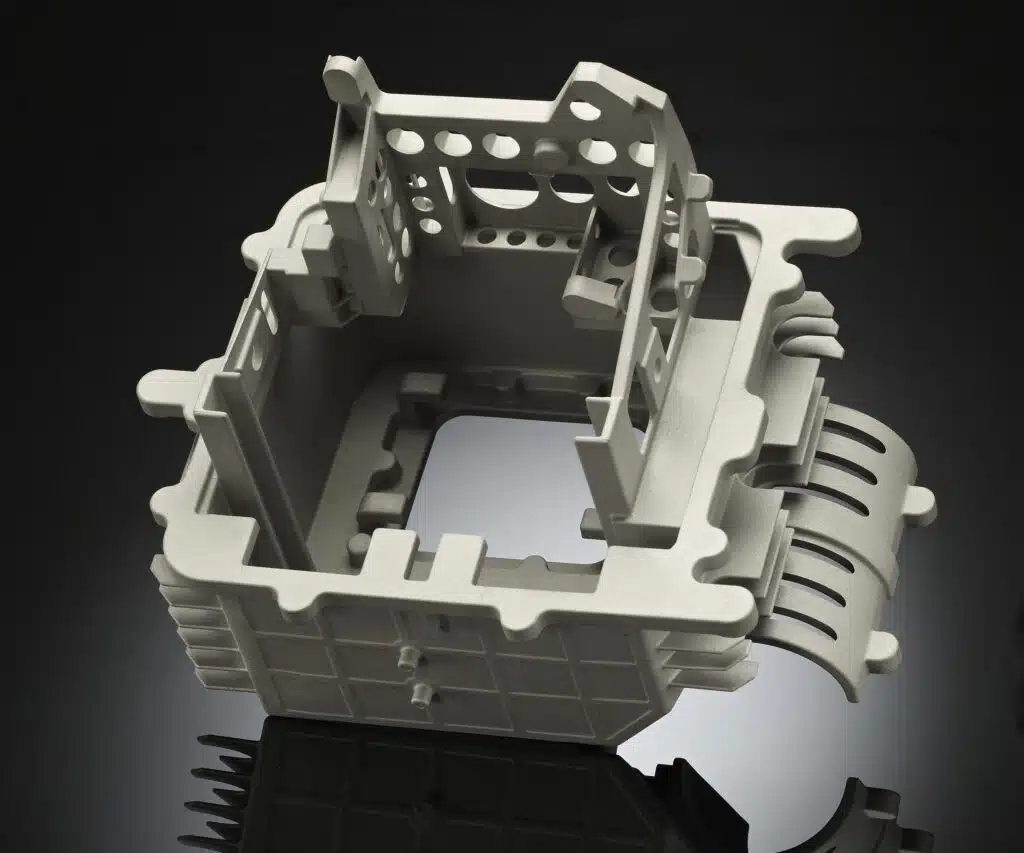

Read MoreThe High Cost of Part Count

One sometimes overlooked aspect of part design is the High Cost of Part Count, that unintended cost for NOT combining the assembled features of a system into a single piece structure. One of the strengths of the casting processes, and in particular that of Investment Casting, is the ability to combine multiple features into one…

Read MoreWhat is an Investment Casting?

Investment Casting is a foundry process known for producing highly accurate, near-net-shape, castings. Once known as the “Lost Wax” process, much as Sand Castings are produced from sand molds, and Die Castings are manufactured from metal dies, Investment Casting derives its name from its ceramic molding material that is known as “Investment”. A technical definition…

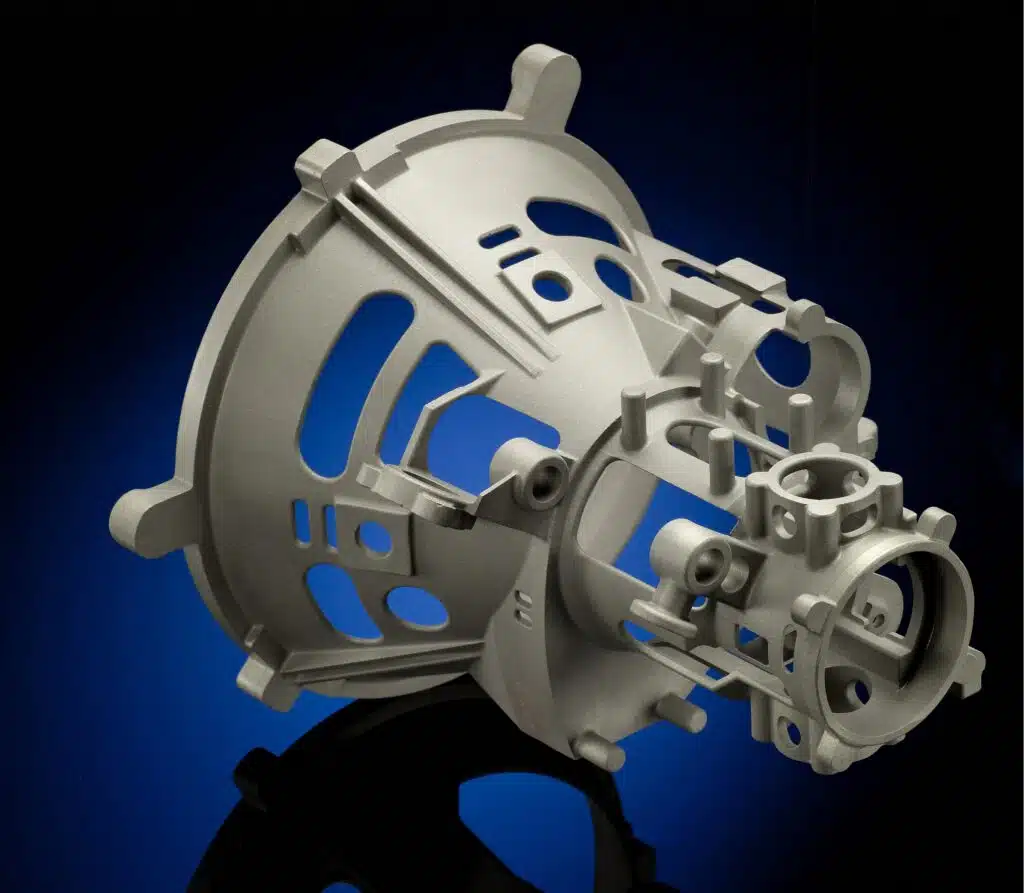

Read MoreCharacteristics of Casting Design – AFS Video

O’Fallon Casting was pleased by a video that has been released by the American Foundry Society on their MCTV – Metalcasting Television. In the video design engineering consultant and author, Jiten Shah, a Product Development Analyst expounds on design elements of O’Fallon Casting’s “Casting of the Year”. Jiten Shah skillfully promotes aspects of “Good” casting…

Read MoreNanocomposite Aluminum Alloys

On Dec 12 2012, Vince Gimeno and Tim Hill of O’Fallon Casting, attended a meeting at the University of Wisconsin-Madison on the ultrasonic dispersion of nanoparticles for strengthening of cast aluminum alloys. The technical presentation was made by University Professor Xiaochun Li, supporting staff and students. The purpose for the meeting is to establish an…

Read MoreInvestment Casting 101

O’Fallon Casting offers Investment Casting-101 classes to its customers to help educate their Engineers on the Fundamentals of Investment Casting design. More than twenty “IC-101” classes were held at customer sites in 2012. IC-101 is intentionally non-promotional and taught in a classroom environment from an industry prospective. A typical IC-101 class begins with an in-depth…

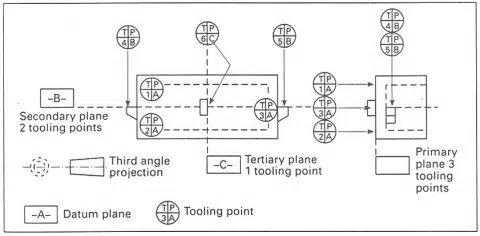

Read MoreCasting Datum Points – Avoiding potential pitfalls of Datum Point selection

Castings provide a cost effect method to provide the Near Net Shape of a configuration, but critical details are inevitably machined. The machining first cut should always be from the Datum Points of the casting, and just in case something goes wrong, it is important to retain the original casting datums. So it is important…

Read MoreCasting Datums and Datum Points – Optimizing their selection

Let us further consider the selection of the datum surfaces. If we visualize a Shoe Box as an example, we may choose either the inner, outer or a combination of each to serve as datum surfaces. My recommendation is that Exterior surfaces should be selected in preference to interior. Consider our Shoe Box and the…

Read More