Technical Articles

The O’Fallon Casting University

To underscore its commitment to its customers and to contribute to our mutual success, O’Fallon Casting has founded “The O’Fallon Casting University”. Castings present a cost effective solution for the manufacture of complex shapes that reduce part count and improve the affordability, manufacturability and reliability of an engineered product. However, successful casting design does require…

Read MoreEdge & Corner Radii

Edges & Corners are external features such as you would see on any cube such as a child’s Alphabet Block. Structurally Edges & Corners have little impact on the strength of a casting. However, Edges and Corners are still an important consideration of casting design. Investment Castings will naturally exhibit a .008” – .012” radius…

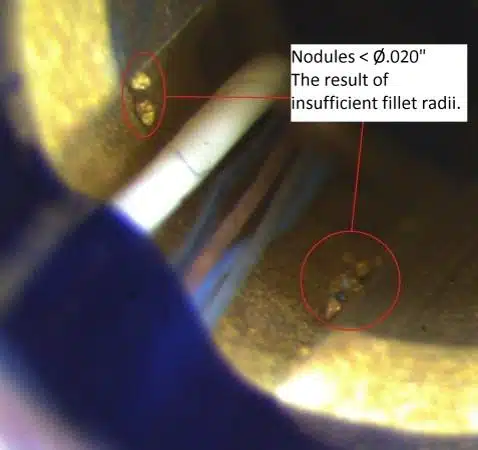

Read MoreWhy Castings need a Fillet Radii

By definition a Fillet Radii is a rounding of an interior corner and are employed on castings to increase their load bearing strength and to improve both manufacturability and quality. For those reasons a fillet radius should be a standard allowance on every casting design. A Fillet Radius makes a structure stronger because it redirects…

Read MoreHow an Investment Casting is Manufactured

Investment Casting is a cost effective method for the production of precise, near-net-shape and complex metal parts. Although Investment Casting is relatively ancient in origin it is today a highly sophisticated manufacturing process. By definition Investment Casting is a foundry process by which a metal casting is produced from a ceramic mold that was formed…

Read MoreThe Five Part Solution

My introduction to the subject of Part Count Reduction came about as an observation of the results of a Design Project in my sophomore year of college. I’ve come to refer to the anecdote as “The Five Part Solution” which might have been long forgotten had the saga not come with an accompanying lesson in…

Read MoreConcurrent Engineering

Customers of O’Fallon Casting are entitled to a free Concurrent Engineering Service to assist in their design of affordable cast products. Concurrent Engineering is remarkably easy to accomplish and is time well spent. O’Fallon Casting hopes that, as a result of Concurrent Engineering, its customers will design better castings and so be more inclined to…

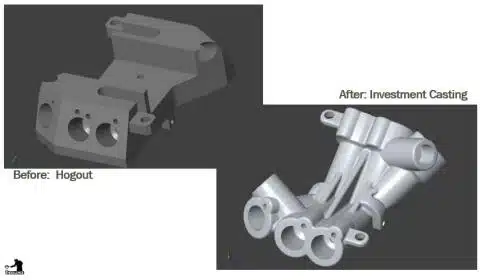

Read MoreThe Characteristics of an Aluminum Investment Casting

The Investment Casting process provides two primary cost benefits to its customers. First is its Near-Net-Shape capability that stems from the dimensional precision of the process and because no draft angle is required. Secondly the Investment Casting process provides an ability to combine multiple pieces into a One-Piece structure with few design constraints and without…

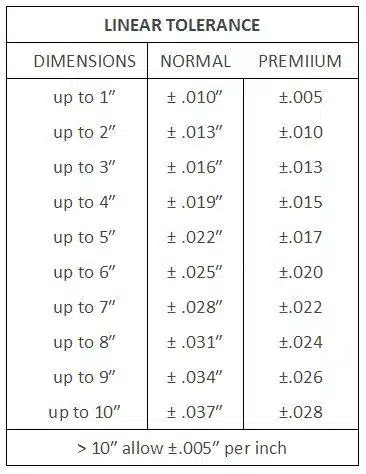

Read MoreStandard Investment Casting Linear Tolerances

Relative to other foundry processes Investment Casting is a very precise method to produce a Near-Net shape cast product. This capability stems both from the repeatability of the process and that a draft angle need not be added to cast surfaces. As with all manufacturing processes there will exist some part-to-part variation that needs to…

Read MoreCasting Conversions

I was looking at an Investment Casting Institute publication entitled Case Studies and Applications which elaborates on the substantial savings realized when fabricated assemblies are converted to One-Piece castings. In that Investment Casting is such an effective manufacturing method for realizing this type of savings one wonders why companies don’t place greater emphasis on achieving…

Read MoreO’Fallon Casting Publishes Design Guide

O’Fallon Casting has published its first “Investment Casting Design Guide” which is now available for free download on the OFC Website. Investment Casting is a cost effect method for the manufacture of complex, near-net-shape, products but some specialized expertise is required for their design. The Design Guide is a natural offshoot of O’Fallon Casting’s “IC-101”…

Read More