By definition a Fillet Radii is a rounding of an interior corner and are employed on castings to increase their load bearing strength and to improve both manufacturability and quality. For those reasons a fillet radius should be a standard allowance on every casting design.

A Fillet Radius makes a structure stronger because it redirects stresses from being concentrated at a sharp interior corner and distributes them over the broader volume of the fillet. The effect of the Fillet Radius is to mitigate a potential weak point of cast structure making transitions within a structure, especially between right angled walls, stronger.

Because of this faculty to mitigate stress concentrations a Fillet Radius also improves the manufacturability of a casting. Castings often require a mechanical “Straightening” operation to restore flatness, perpendicularity and parallelism to the part and a filleted corner is less prone to cracking during this operation. Better casting manufacturability provides a foundry with control of its costs and promotes more consistent deliveries.

The foundry industry works diligently to avoid turbulence in the flow of hot metal as their products are being cast. Turbulence can cause a mixing of the metal with air to trap gas or lead to the formation of oxides that may become embedded in the casting. Fillet radii help to minimize the turbulence in the metal as it flows through the cavities of the mold thus inhibiting the formation defects from oxides and trapped gas and so contributes to the better quality of a cast product.

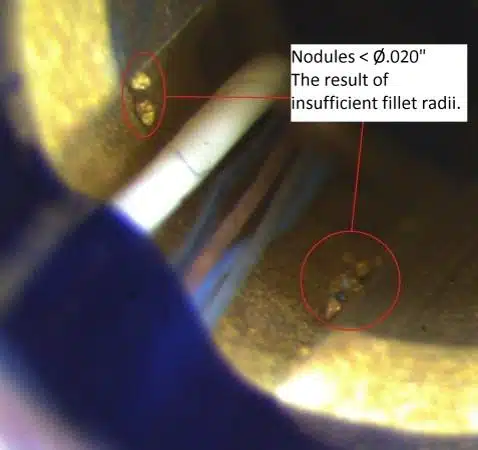

In the Investment Casting process a thickness of ceramic shell is formed about a pattern assembly by repeated dips of the assembly into slurry. Sharp internal corners in a part configuration can provide nucleation sites onto which bubbles of air form and adhere to the pattern while the slurry is being applied. Air bubbles on the pattern will become small voids in the ceramic shell that will subsequently fill with metal and become positives on the surface of the casting. A fillet radius improves the ability for the pattern to shed air bubbles as the slurry is applied thus reducing the propensity of casting to exhibit positive metal.

A general “Rule of Thumb” for an aluminum investment casting is to apply a fillet radius equal to 1x to 1.5x of the wall thickness with a recommended minimum of .06”R. It is also advisable to specify fillet radii with a Max tolerance.

Customers of O’Fallon Casting are provided a free Concurrent Engineering serviceto assist in their design and improve their use of castings. If you have questions regarding Fillet Radii or other investment casting design considerations call yourO’Fallon Casting Sales Engineer for assistance.