Technical Articles

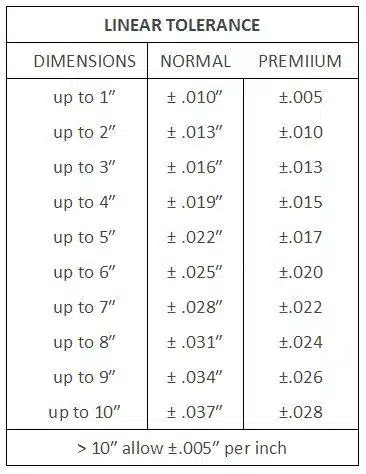

How Big is 5 Thousandths

How big is .005 Inch? In everyday life it is very small. In astronomic and geologic terms the moon moves further from the earth by .004 inches and North America moves .002 inches further from Europe each day. Your fingernails grow at a daily rate of approximately .004 inch. As people relate to things more…

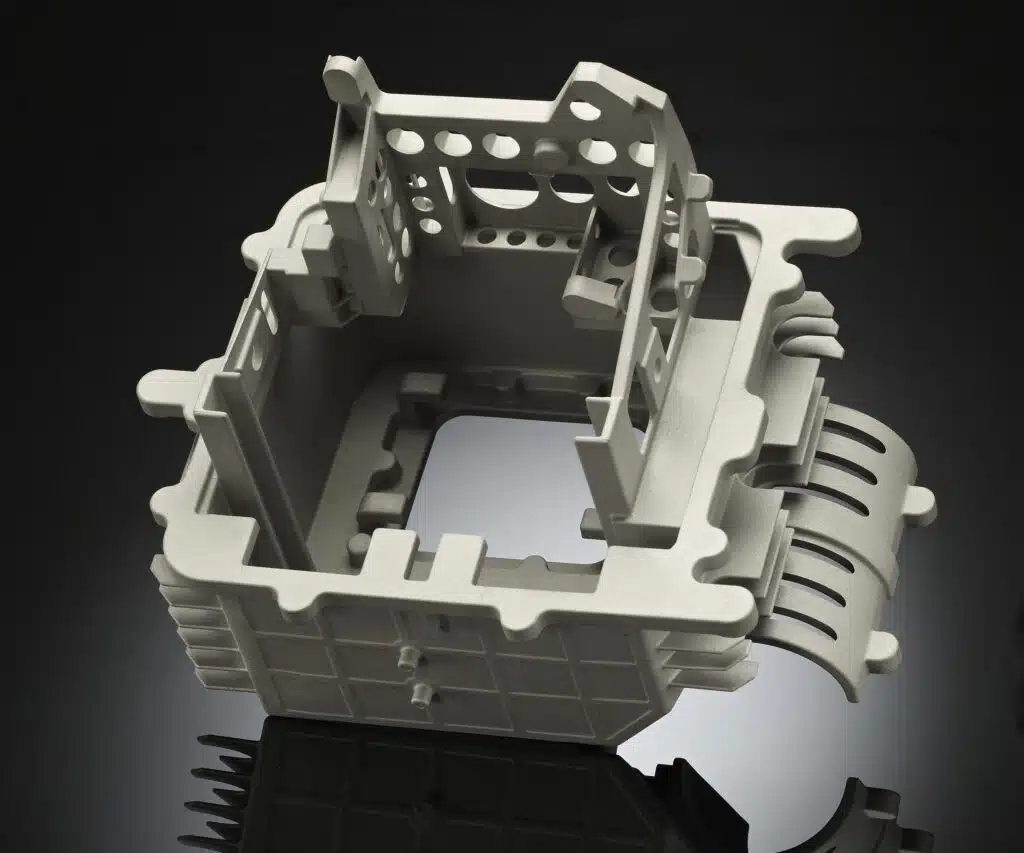

Read MoreHow does an Investment Casting Improve Product Affordability?

Many confuse the word “Affordability” with the word “Price”. They are not the same and there are quite a large number of articles available that are devoted to defining Affordability. The short rendition, however, is that Affordability equates to the total cost of ownership. Let’s say that a friend offers you a good price on…

Read MoreA Case Study in Collaborative Engineering

Over the years, we have had the pleasure of having participated in numerous Collaborative Engineering events, several of which were quite unforgettable. One instance occurred about ten years ago and began with a rather panicked phone request from an owner of a machine shop. As it stood he was seriously delinquent on a contract because…

Read MoreMinimizing Unintended Costs

Minor oversights during the design phase of a casting can lead to unintended downstream costs. Let us consider two case studies we have encountered recently as examples of how overlooking the requirements of specifications on your drawing can lead to extraneous manufacturing steps. The first was a complaint from a Quality Engineer at company that…

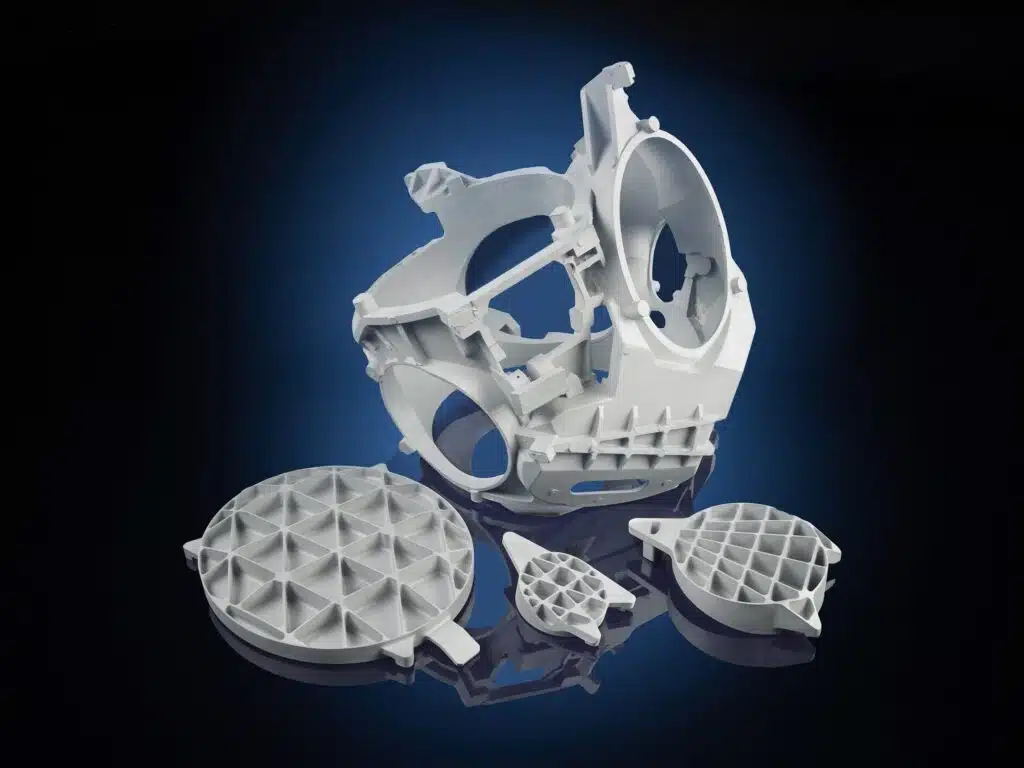

Read MoreAdvantages of Investment Casting for the Manufacture of Metal Matrix Composite Alloy Castings

As it is with other hard alloys such as inconel or even stainless steel, the secondary machining of MMC castings is a significant cost component of their manufacture. The near-net-shape advantage and the greater freedom of design that is inherent with the Investment Casting process provides opportunities to greatly reduce or eliminate machining content of…

Read MoreThe Customizable Properties of Metal Matrix Composite Alloy Castings

Although increasing development activities have led to system solutions using metal composite materials, the use of especially innovative systems, particularly in the area of light metals, has not been realized. The reason for this is insufficient process stability and reliability, combined with production and processing problems results in inadequate economic efficiency. Application areas are very…

Read MoreInvestment Casting (Al/SiC) Metal Matrix Composites

The particulate Silicon Carbide reinforcement in Aluminum Alloy Metal Matrix Composite enhances this lightweight material with improved mechanical property attributes for stiffness, vibration dampening, wear resistance, high thermal conductivity, and low coefficient of thermal expansion. With its unique set of properties MMC alloys have been employed in diverse applications such as moving structures in high…

Read MoreThe O’Fallon Casting Advantage

O’Fallon Casting is a world recognized leader in the manufacture of nonferrous investment castings. It has been recognized for its excellence by the receipt of a U.S. Small Business Administration “Subcontractor of the Year” Award. As a member of both the Investment Casting Institute and the American Foundry Society O’Fallon Casting has been honored as…

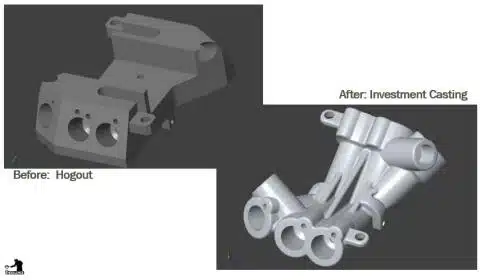

Read MoreIC-201

The Investment Casting Process offers Engineers the opportunity to enhance the affordability of their designed products by combining multiple pieces into a single near-net-shape structure that reduces both the need for secondary machining and the part count of an engineered assembly. However, good applications for employing the IC process are often poorly understood so excellent…

Read MoreAMS 2175 Casting Visual Standards

All products contain some degree of imperfection. Imperfections that don’t affect the functionality of a product are essentially cosmetic where others, if undetected, could result in a catastrophic failure. Nondestructive testing methods are commonly used with castings to detect irregularities that they may be assessed to a standard as defined on an engineering drawing. For…

Read More