Posts by ofalloncasting

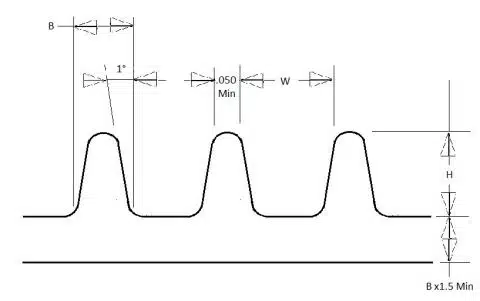

Investment Casting of Slots & Fins

Slots and fins are common features that appear often on Investment Cast parts and typical of configuration that can be incorporated into a design with minimal impact on the cost. There are, however, some basic rules-of-thumb for the design of slots and grooves to help keep them from becoming cost drivers. Let’s begin with a…

Read MoreInvestment Casting Internal Cores

One of the special capabilities of the investment casting process is the production of castings with internalized features, passageways or undercuts. O’Fallon Casting has four techniques available to produce internal detail: mechanical tooling, soluble wax cores, pre-formed ceramic cores and imbedded pre-formed tubing. We’ll expand here on each of these four techniques. Hard tooling provides…

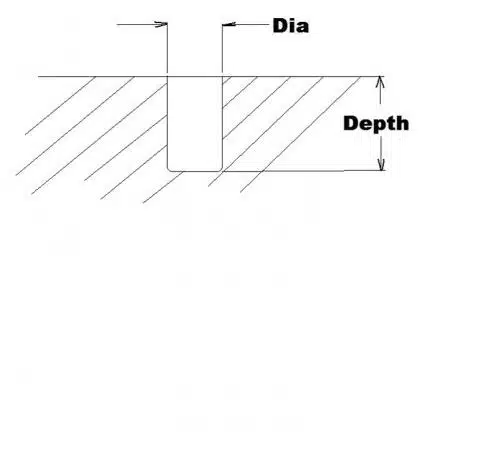

Read MoreInvestment Casting Blind Holes & Pockets

Blind holes and pockets are common features of investment casting designs. They serve to lighten the part, provide designed clearances and are examples of the type of detail that can often be provided by the investment casting process at negligible cost to a customer. For any feature to be castable, it is necessary for an…

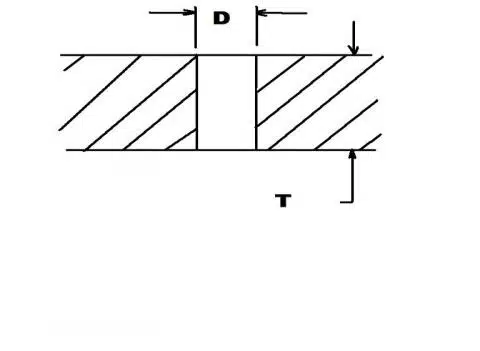

Read MoreInvestment Casting “Through-holes”

A common question asked by Design Engineers in concurrent engineering is whether a particular hole in a part is castable? To answer that question requires an analysis of the four dimensional components that constitute the description of the hole: diameter, length, diametrical tolerance and locational tolerance. First, I should be very clear that the casting…

Read MoreModel Based Definition – Advantages & Disadvantages

Prior to the widespread integration of CAD systems in the 1980’s part drawings were filled with leader lines to features delineated by dimensions for size and location with independent tolerances. CAD systems have made the designing of parts both better and quicker and have a positive impact downstream from product design. Also known as Digital…

Read MoreLaser Engraved Part Marking

O’Fallon Casting provides its customers with a better alternative and consistently legible option for the application of variable part marking information on castings: Laser Engraved Part Marking. This OFC technology eliminates customer complaints and rejections of castings for poor legibility of manually applied vibro-peened or ink stamped part marking. O’Fallon Casting’s Laser Engraved Part Marking…

Read MoreGeometric Dimensioning and Tolerancing of Castings

There is nothing really new about Geometric Dimensioning and Tolerancing so I was surprised by a question an engineer asked recently concerning GD&T. I had just finished speaking to a group of engineers about investment casting design and the first question asked was to express my opinion of “GD&T casting drawings”. Admittedly confused I lamely…

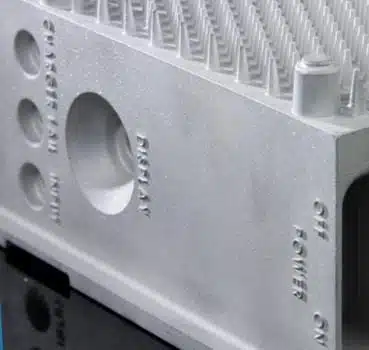

Read MoreIntegrally Cast Lettering & Marking

One of the primary benefits provided by the Investment Casting process is that part detail can very often be furnished at negligible additional cost. Engineers frequently take advantage of this “free” capability by incorporating cast lettering and marking into their part designs. Marking can be almost anything from letters, numbers, logos, trademarks or be simply…

Read MoreSurface Texture of Investment Castings

The Investment Casting Institute’s “The Investment Casting Handbook” states that a 125 RMS surface texture is typical (for steel castings) and that no other casting process produces a finer surface finish than does investment casting. Although “The Investment Casting Handbook” says Typical, a 125 RMS is commonly cited by the industry and a 125 RMS…

Read MoreIn-Process Weld Rework

Castings are susceptible to having small discontinuities such as inclusions, voids, cracks, etc. that are cosmetically unappealing or potentially even a cause of end product failure. In-process weld rework of castings, sometimes also referred to as “cosmetic weld repair”, is a routine and commonplace foundry activity that is used to mend such casting discontinuities. A…

Read More