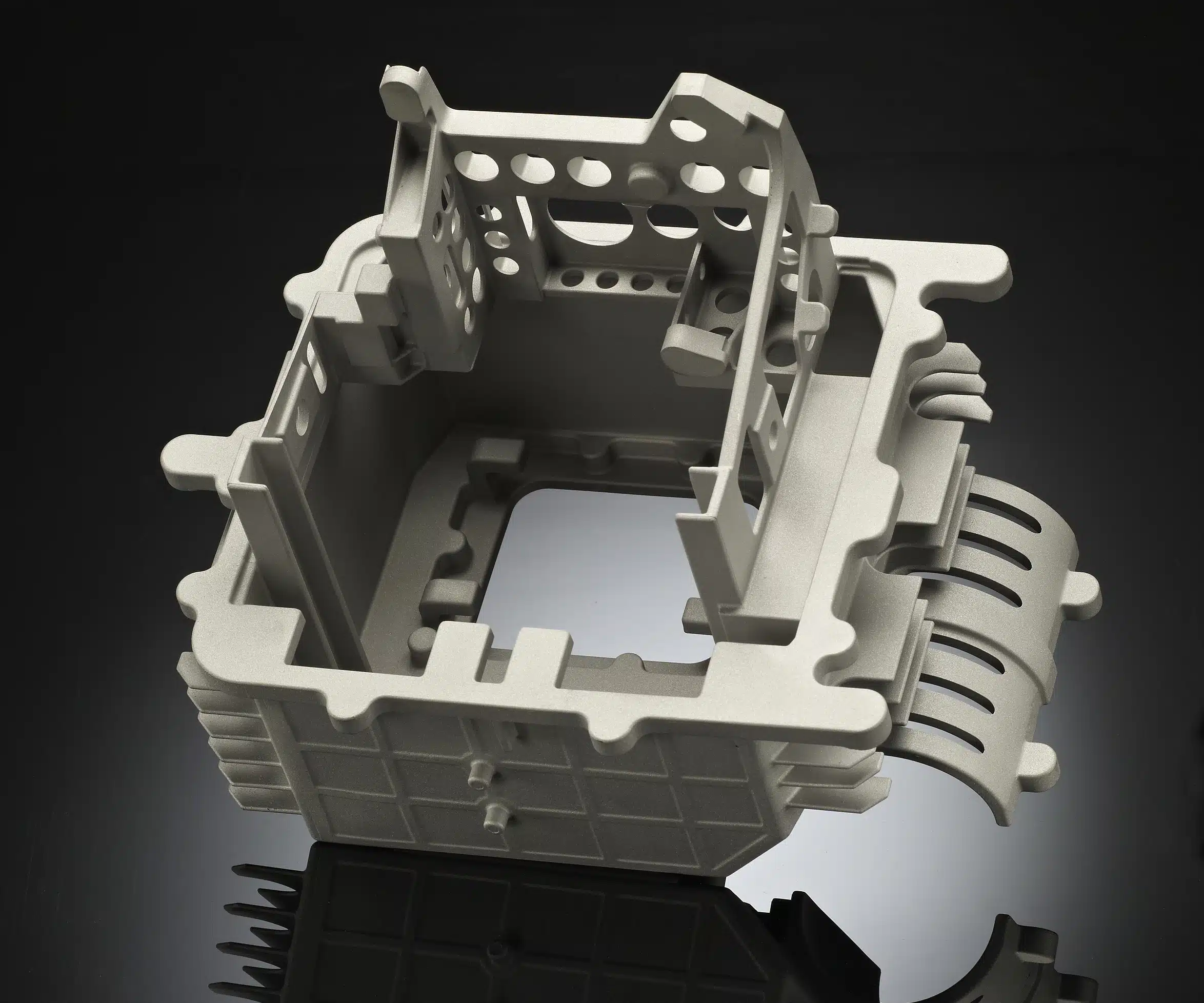

One sometimes overlooked aspect of part design is the High Cost of Part Count, that unintended cost for NOT combining the assembled features of a system into a single piece structure. One of the strengths of the casting processes, and in particular that of Investment Casting, is the ability to combine multiple features into one consolidated design that reduces the Part Count and enhances both the affordability and reliability of a system.

Simply stated, Part Count is “the total number of separate parts in an engineered system” and there are numerous articles and abstracts available concerning the subject. Many businesses do utilize Part Count as a design-to-cost factor, but I am also surprised to find that some do not.

If you consider the “Cost Stream” for any single part in a system, the accumulated cost for procurement can be staggering. Here’s a short list of downstream costs for each new part design:

- Design Approval, Data & Control and the Make / Buy Decisions

- Production Planning, Purchasing Requisitions and Purchasing

- Tooling Construction and Proofing

- Manufacturing, Inspection and Testing

- Shipping, Receiving, Inspection and Inventory

- Part Assembly and Testing

When you consider the duplicative costs that are absorbed for each individual part in a system, it is easy to understand the value of a lower Part Count. Even in an instance where the per-unit-price of a complex part might be greater than the total of multiple simplified pieces, there is still inherent value in designing them into a single cast structure.

Furthermore, every assembly point in a system does carry some risk of system failure that impacts warranty costs. A lower Part Count, which is the result of fewer assembly operations, should also improve system reliability.

Often Part Count reduction only becomes a consideration once a system is in the field. At this late point, however, the costs for redesign, additional tooling and testing will often discourage effective action. Part Count reduction, therefore, is most effective if implemented early in the design process at the point where the System Assembly points are identified. Concurrent Engineering input from a foundry can be invaluable at this point.

Generally speaking a lower Part Count can enhance both the affordability and reliability of a designed system. Castings are an effective design option to eliminate assembly operations and reduce a system’s Part Count.

Casting design does, however, require some specialized expertise. To that point O’Fallon Casting provides its customers with Concurrent Engineering Services to assist them in reducing the Part Count of their systems. OFC also offers itsInvestment Casting-101 class to teach the basics for good casting design.

If you have any questions, contact your O’FallonCasting Sales Engineer.