Customers of O’Fallon Casting are entitled to a free Concurrent Engineering Service to assist in their design of affordable cast products. Concurrent Engineering is remarkably easy to accomplish and is time well spent. O’Fallon Casting hopes that, as a result of Concurrent Engineering, its customers will design better castings and so be more inclined to engineer other parts as foundry products.

The effectiveness of Concurrent Engineering is of course greatest when initiated very early in the design process. Experience tells us that once the component part designs become finalized it becomes difficult to affect change.

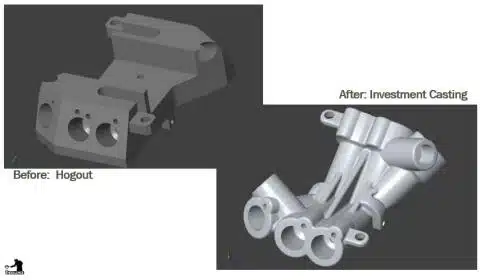

The primary benefit of Concurrent Engineering is to design a more manufacturable product that minimizes cost drivers. Concurrent Engineering also offers the foundry an opportunity to make suggestions such as combining multiple parts into the single cast piece that will enhance the total value of the product.

In addition to the direct benefit of designing a more affordable product the Concurrent Engineering process also serves to grow a customer’s internal expertise. When armed with an appreciation for the capabilities of the investment casting process customer designers will more readily identify opportunities to optimize the configuration of their engineered assemblies.

Investment Casting provides the most freedom and is the most straightforward foundry process for which to design. This flexibility is in-part because a draft angle need not be taken into consideration but also because the process is less restrictive in producing configuration such as undercuts and cored holes.

O’Fallon Casting’s Concurrent Engineering Service is an efficient and effective method for Engineers to obtain that specialized expertise that will help them design affordable and manufacturable cast products. For more information please contact O’Fallon Casting.