O’Fallon Casting is the preeminent manufacturer of Investment Cast Al/SiC Metal Matrix Composite (MMC) castings in the world today. Its family of cast MMC’s contains particles of Silicon Carbide, ranging in size of 9 to 38 microns, homogeneously suspended in an aluminum matrix. The particle density can be varied, from 20%-40% Silicon Carbide by volume to create different properties of MMC.

Although MMC’s are difficult to machine, Investment Casting produces them in Near Net Shapes that helps to minimize the machining content.

Al/SiC MMC’s have Coefficients of Thermal Expansion and Specific Stiffness similar to cast Beryllium Aluminum but without the potential health hazard.

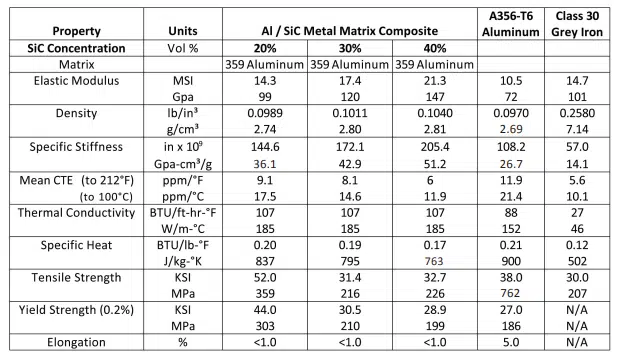

Al/SiC MMC’s offer very desirable material properties:

Typical Property Comparison of AI/SiC MMC and Traditional Engineering Alloys