As it is with other hard alloys such as inconel or even stainless steel, the secondary machining of MMC castings is a significant cost component of their manufacture. The near-net-shape advantage and the greater freedom of design that is inherent with the Investment Casting process provides opportunities to greatly reduce or eliminate machining content of MMC castings. Therefore the successful implementation of cast-MMC can be dependent upon possessing the necessary engineering skills to design products that take advantage of the Investment Casting process.

For Engineers, the near-net-shape advantage means that only critical surfaces need be machined. Raised pads & undercuts can be employed to relieve the surrounding area of the part. Only minimal amounts of machine stock need be added to these machined features to assure cleanup.

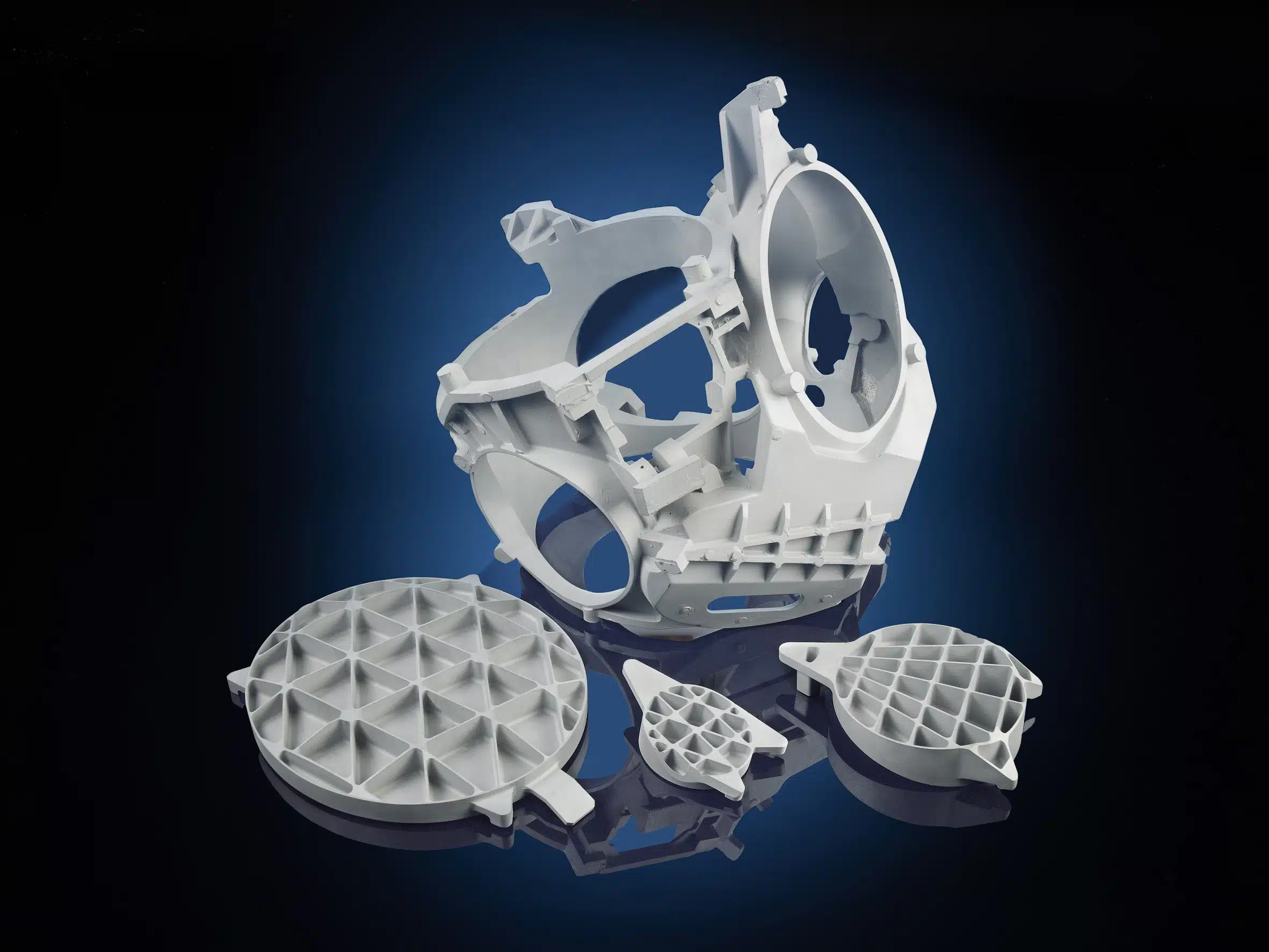

Investment Casting is also known for its ability to generate savings through the reduction in the Part Count of an engineered assembly. O’Fallon Casting’s 2013 AFS “Casting of the Year” was an important example of a part design that employed the power of the IC process to accomplish part count reduction. This capability is particularly beneficial when designing for MMC as the fewer assembly points of a unitized structure also correlates to a reduction in the cost for machining.

Additionally prices for Investment Castings are less sensitive to the complexity of a structure than in other foundry processes. Features such as undercuts, cored holes, cooling fins & pins, connector holes, etc. are commonly cast by investment casting and all without the need to consider a draft angle. Engineers are encouraged to incorporate this detail into their cast MMC configurations as these design nuances come at minimal additional expense.