Many confuse the word “Affordability” with the word “Price”. They are not the same and there are quite a large number of articles available that are devoted to defining Affordability. The short rendition, however, is that Affordability equates to the total cost of ownership.

Let’s say that a friend offers you a good price on a used car. On the surface the deal looks pretty sweet as the car is in good condition and it gets good gas mileage, so you buy it. Halfway home with your new purchase it breaks down. You have it towed to a service station and find that although they can fix the vehicle they’ll need to order the parts so the repairs can’t be completed until sometime next week and they want $1,000 deposit on the parts and labor. The car doesn’t appear to be such a good purchase now, does it? Although the car did have a good purchase price it is not affordable, plus now you’re stuck with selling the used car and you’ve lost a “friend” to boot.

So Affordability is comprised of much more than just price. Considerations for availability, reliability, inventory and administrative costs should all factor and Investment Castings improve product Affordability from each of these aspects.

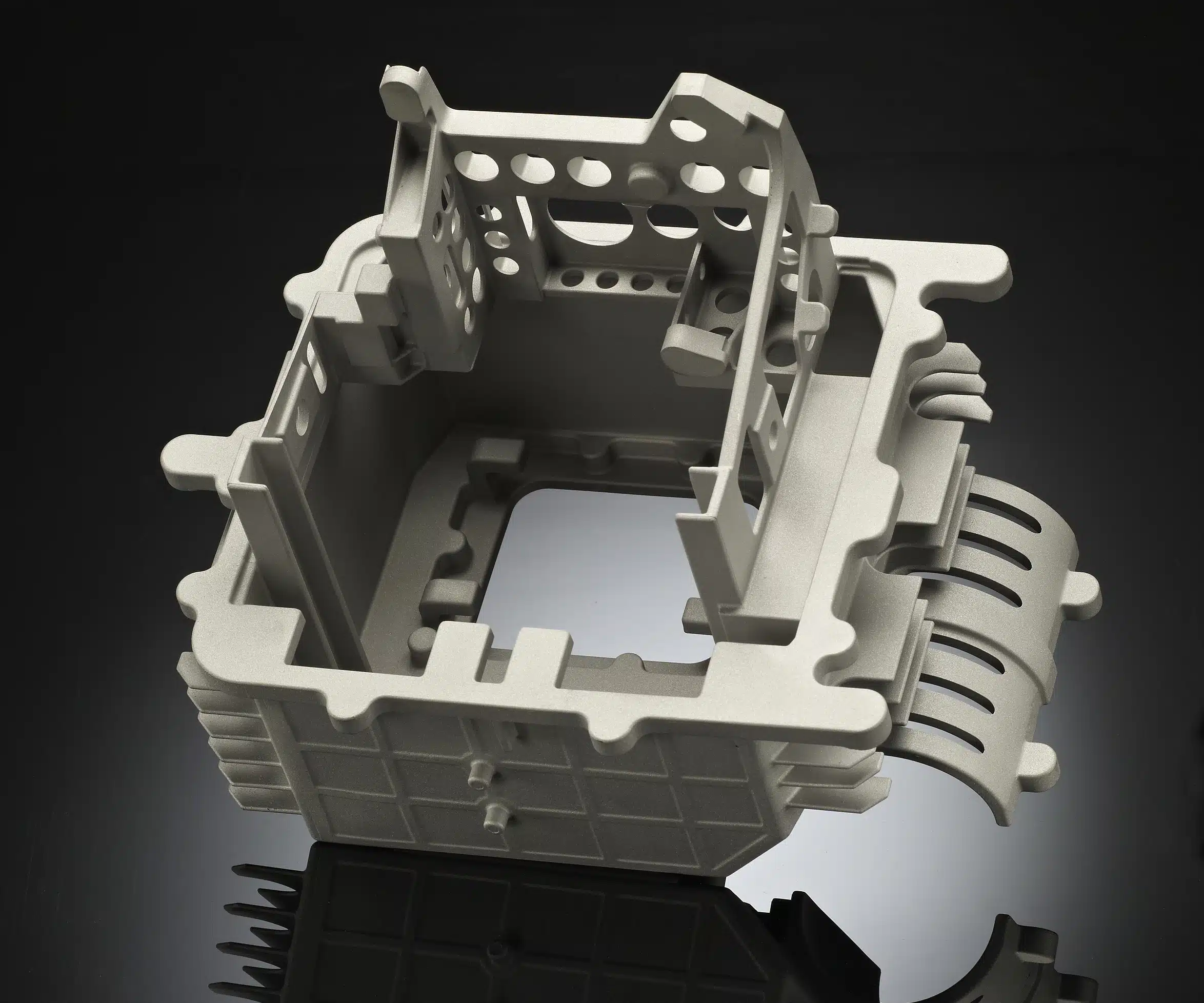

As Investment Casting excels at manufacturing complex shapes, let’s take an example of an Engineer who designs a 1-piece Investment Casting instead of a 5-piece Assembly. Perhaps the price of the 1-piece Investment Casting might even be greater than the combined price for the five assembly elements. But consider also the cost for:

- Procurement of 1-piece vs. 5-pieces.

- Receiving & Incoming inspection of 1-piece vs. 5-pieces

- To and From stock of 1-piece vs. 5-pieces

- Work instructions for the 5-piece assembly

- Assembly and inspection of 5-pieces and cost for fasteners

- Accounting costs for 1-piece vs. 5-pieces

And then there are also contingency considerations:

- Delays if 1 of 5 pieces is delivered late

- Administrative and Quality oversight for 5 instead of 1

- Inventory from having too many of 1 of 5

- Administrative costs for expediting

Your Engineer has made a good decision by designing a 1-piece investment casting as the benefits from Part Count reduction from 5 to 1 are enormous and, as every assembly point is also a potential failure point, the product integrity of a 1-piece structure is superior to that of a 5-piece assembly.

All of these affordability costs are a function of design decisions and to help our Customers make good engineering choices we offer the O’Fallon Casting University. The OFCU is a comprised of both O’Fallon Casting sponsored classes and customer services that include:

- IC-101 is a 3-hour class taught at customer locations on the fundamentals of Investment Casting Design.

- IC-201 is a 3-day class conducted at O’Fallon Casting on the basics of Investment Casting Manufacture.

- Concurrent Engineering is OFC’s interactive and collaborative design service to optimize customer casting designs.

- O’Fallon Casting Design Guide is a free downloadable guide on the OFC website containing the rules-of-thumb for investment casting design.

- Technical Articles on the OFC website that provide insight into casting topics.

Since 2011 more than 1000 Customer/Engineers have availed themselves of the IC-101 & IC-201 classes offered by the O’Fallon Casting University.

If you have any questions regarding the Affordability advantages of an Investment Casting or about the O’Fallon Casting University, please contact your O’Fallon Casting Sales Engineer for further information.