Investment Casting is a foundry process known for producing highly accurate, near-net-shape, castings. Once known as the “Lost Wax” process, much as Sand Castings are produced from sand molds, and Die Castings are manufactured from metal dies, Investment Casting derives its name from its ceramic molding material that is known as “Investment”.

A technical definition of the Investment Casting process is “A foundry process by which a metal part is produced from a ceramic (Investment) mold that was formed by a heat-disposable (wax or plastic) pattern. The earliest known evidence of the Investment Casting process was more than 5000 years ago in ancient China. Other early civilizations in Asia, Africa, Europe and the Americas are also found to have utilized the process.

Through most of history Investment Casting was largely used for the manufacture of custom jewelry, sculpture and art. However, in the 1930’s the Investment Casting process was rediscovered when its ability to cast near-net-shape parts was found to be advantageous for the manufacture of components for aircraft & arms during World War II.

Following the War, the use of Investment Casting began to expand into broader markets. In 1953 a coalition of Investment Casters, and their suppliers, formed the Investment Casting Institute which then established design guidelines to aid Engineers to better design for the process

Today, Investment Casting foundries exist in many countries around the globe, serve in a vast array of markets and are manufactured in a stunning variety of metals. O’Fallon Casting itself specializes in the Investment Casting of Aluminum and Silicon Carbide / Metal Matrix Composite alloys.

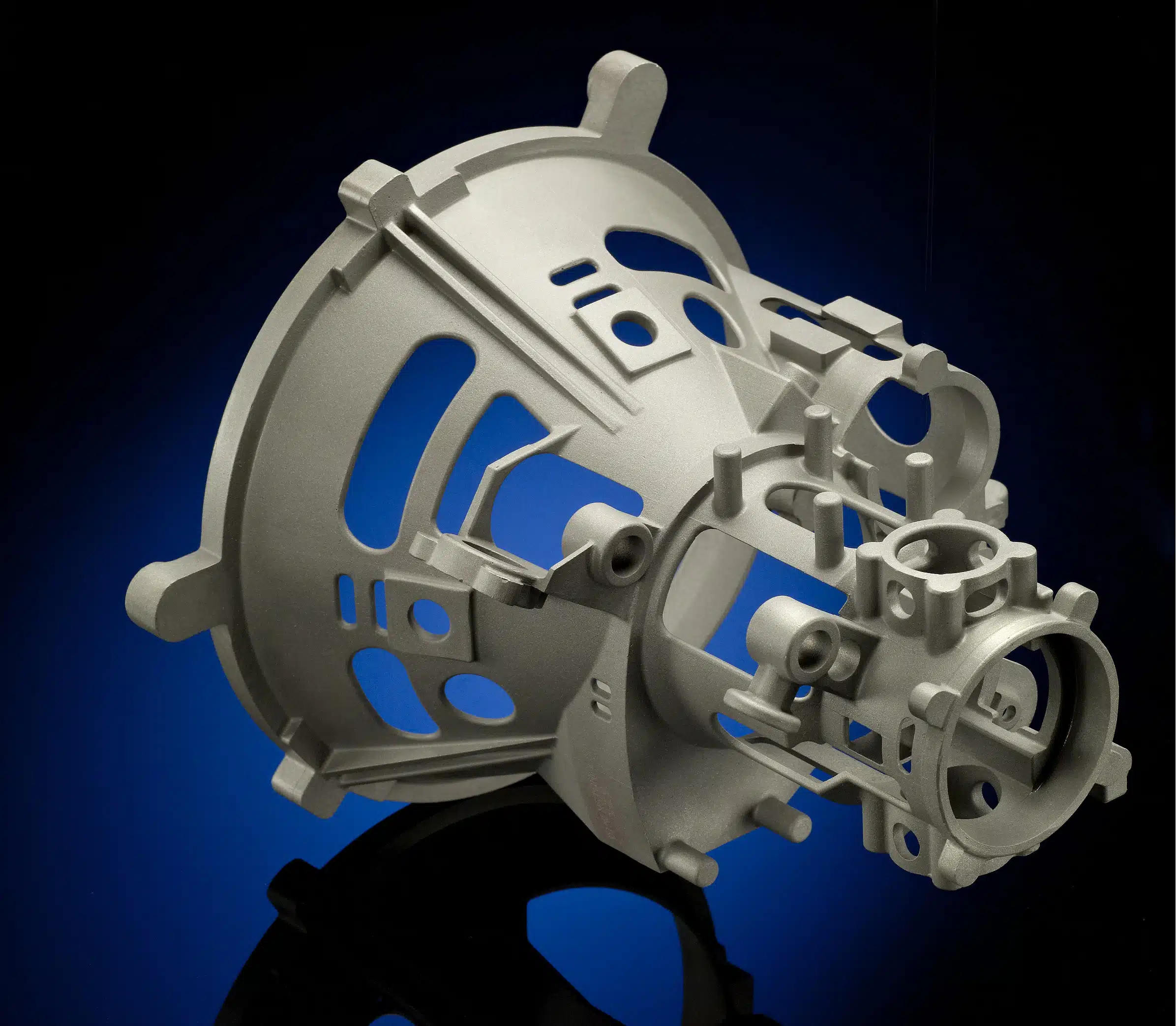

Engineers continue to discover the ability of the Investment Casting process to manufacture highly detailed and accurate shapes that reduce weight, improve functionality, or reduce part count.

If you have any questions, please contact us at: sales@ofalloncasting.com